About Us

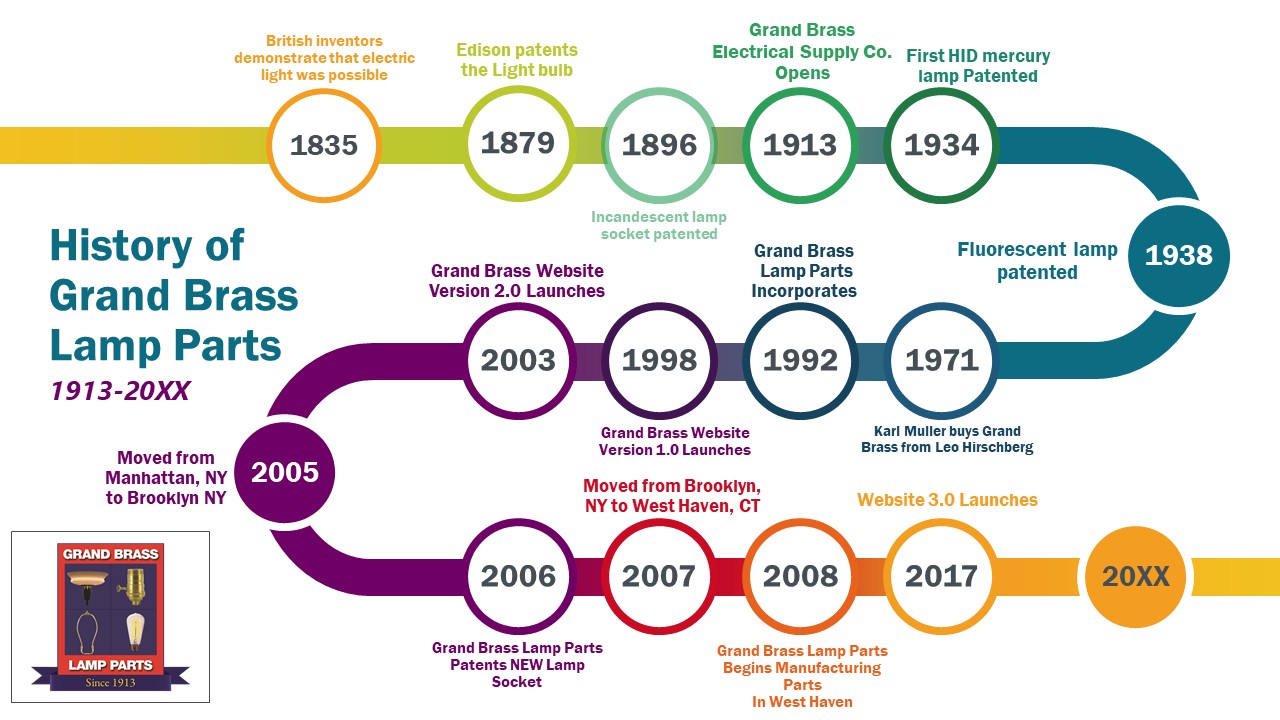

Grand Brass Lamp Parts has served the Retail and wholesale lamp parts, lighting parts, and chandelier parts industry since 1913. We are the oldest supplier of lamp making supplies in the USA.

With a foundation that dates back over a century, the company has continuously evolved to meet the changing needs of the lighting sector, from the early days of oil and gas lighting to the modern era of electrical lighting.

Our contribution includes offering a vast selection of lamp parts, lighting parts, chandelier parts, and much more, catering to a wide range of customers including retail, wholesale, lighting manufacturers, repair shops, and hobbyists.

|

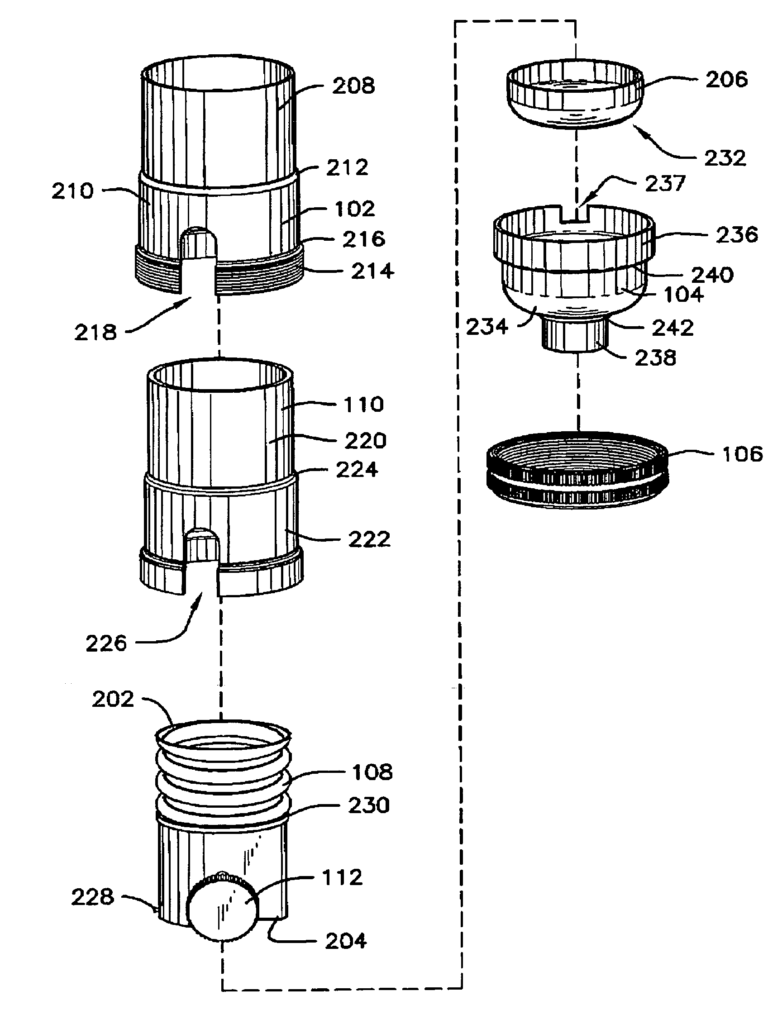

One of the key ways Grand Brass Lamp Parts has influenced the industry is through its innovative product offerings. We have developed patented designs, such as our brass shell and locking screw ring socket design, known for its durability and aesthetic appeal. This design is just one example of how the company combines functionality with beauty, setting a standard in the market for high-quality lamp parts. |

Furthermore, Grand Brass Lamp Parts provides a diverse range of products, from switches, swivels, lamp shade making supplies, transformers, as well as replacement lamp glass and lighting glass such as 2-1/4" fitter glass shades, torchiere glass shades, student shades, and many styles of antique reproduction glass shades. We carry a large selection of lamp parts and chandelier parts including lamp sockets, crystal prisms, chandelier ceiling canopies, lamp wire, cord switches, lamp dimmers, floor lamp glass, fixture chain and all the supplies for making lamps, showcasing our commitment to being a one-stop-shop for lighting needs. Our offerings extend to decorative components as well, including crystal pendants, arms, and balls, highlighting our role in not just the functional aspect of lighting but also in the decorative and aesthetic enhancements of lighting fixtures.

By maintaining a broad and comprehensive catalog, Grand Brass Lamp Parts supports both the restoration of antique lighting fixtures and the creation of new, custom lighting designs. This dual focus not only preserves the rich history and craftsmanship of past lighting designs but also encourages innovation and creativity in modern lighting projects.

Overall, Grand Brass Lamp Parts' extensive product range, combined with their commitment to quality and innovation, has contributed significantly to the evolution and diversity of the lighting industry, enabling professionals and enthusiasts alike to realize their lighting projects with components that meet high standards of functionality, beauty, and durability.

Grand Brass Lamp Parts is not only a distributor but also a manufacturer of lamp parts and lighting hardware. This means we have the capability to produce a variety of components in-house, which can include custom manufacturing services for specific projects or unique requirements. Manufacturing our own parts allows Grand Brass to offer a wide range of specialized items and ensures that we can maintain high quality standards across their product lines. Our role as a manufacturer also enables us to respond more flexibly to the needs of the market and our customer's needs, including offering custom solutions or rapidly producing parts to meet specific demands.

Our Capabilities

- * Wire Manufacturing and Processing of Cloth Covered Wire and Powercords

- * UL Listings and Assembly

- * Manufacturing and Machining of Turn and Cast Metal

- * Branding and Lazer Engraving

- * 10,000+ items in stock at our Fulfillment Center

Grand Brass Lamp Parts, LLC is a company known for providing a wide range of lamp parts and lighting hardware. We cater to the needs of lighting manufacturers, repair shops, antique restorers, and hobbyists, offering products that range from lamp sockets, lamp wire, and lamp bases to chandelier parts, lamp glass, and decorative bulbs.

Our extensive inventory includes both modern and vintage-style components, making it possible for customers to repair, create, or restore lamps and lighting fixtures to their desired specifications.

Established for many years, Grand Brass Lamp Parts has built a reputation for its broad selection of high-quality parts, competitive pricing, and excellent customer service. We typically serve our customers through an online platform, allowing for easy browsing and purchasing of products. The company is known for its expertise in the field, often providing guidance and advice on lamp making and repair projects.

Let us be your lamp making parts supplier.